Atlas Copco

Waterwell compressor

Range: 1000 to 1250 cfm Application: Borewell / waterwell deeper drilling

Read More

Shallow waterwell compressor

Range: 450 to 750 cfm Application: Shallow waterwell drilling

Read More

Handheld tools

Pneumatic Rock drills / Jack hammers Pneumatic dust collector Scablers and needle scalers Post puller

Read More

HiLight V5+ LED light tower

Single cylinder LED light tower 2 cylinder LED light tower Applications: Mining, road construction, building

Read More

Electric portable air compressors

Range: 300 to 475 cfm 45 to 75 KW 90 to 132 KW Applications: Mining,

Read More

Portable diesel air compressors

Range: 300 to 650 cfm Applications: Mining, construction, sandblasting, cable blowing etc

Read More

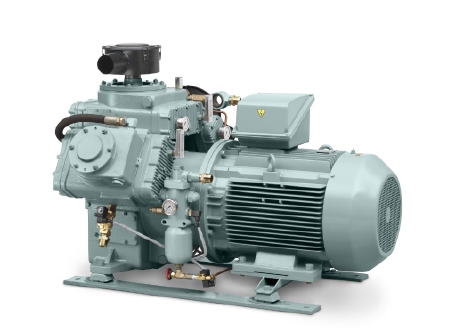

LT KE 25-125: Water-cooled piston compressors for starting air, 18.5-90 KW / 25-125 hp

The harsh marine environment demands the most durable and most reliable products: you do not

Read More

LE Snow: Oil-lubricated piston compressor for snow making, 1.5-15 kW / 2-20 hp

tlas Copco LE-Snow piston compressors are designed specifically for the snow-making industry. The LE-Snow provides

Read More

LE / LT: Industrial oil-lubricated aluminum piston compressors, 1.5-15 kW / 2-20 hp

Looking for a durable, high-performance compressed air solution for your specific industrial application? Designed with

Read More