Features & benefits

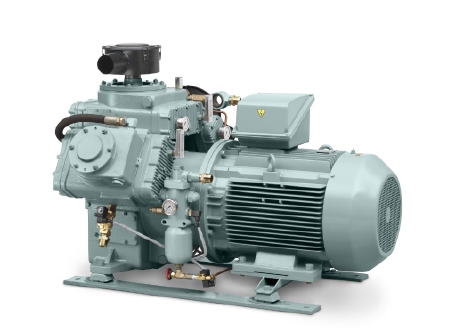

Solid reliability – Forced air flow around the crankcase reduces condensate to zero and extends bearing life. The LT KE can be cooled with sea water or fresh water. The LT KE has no electronic sensors, but pressure and temperature gauges for an easy, fast and reliable read-out.

Low running costs – Operational costs are limited and due to the use of highly durable components the compressors have a long lifetime and long maintenance intervals. Synthetic oil is used as standard.

Space saving – LT KE compressors are characterized by a small footprint and there is no need for a canopy. Supplied with a baseplate and delivered as plug-and-play unit, they allow for quick installation.

The harsh marine environment demands the most durable and most reliable products: you do not want critical equipment to break down at sea. That is why you need the Atlas Copco range of LT KE starting air compressors. Built to last, they will give you the performance and reliability you need.

The LT KE starting air compressors have capacities up to 125 hp. They withstand ambient temperatures up to 60°C, which makes them ideal for installing in an engine room.

| Capacity FAD (m³/h, cfm) |

55 – 398 m³/h |

| Installed motor power |

15 – 90 kW |

| Working pressure |

30 bar(e) |

| Capacity |

60-430 m³/h |