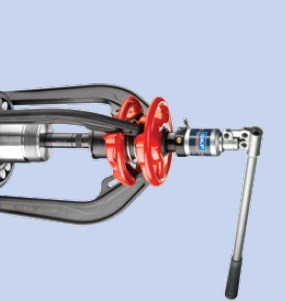

Mounting/dismounting tools (Fitting

tools, induction heaters, pullers,

hydraulic pumps, etc.)

Alignment tools (Shaft and belt

alignment tools)

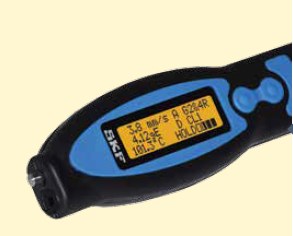

Instruments (Tachometer,

stroboscope, temperature gun,

thermal imager, endoscope, etc.)

All posts by Come on Kasi Sales

Power Transmission

The SKF Power transmission

product range includes six main

areas:

Belts

Pulleys

Chains

Sprockets

Couplings

Bushings and Hubs

Solution Products

CARB toroidal roller bearings

INSOCOAT bearings (insulated

bearings)

High temperature bearings & units

Hybrid bearings

Sealed Spherical Roller Bearings

Customized Housings

Bearings & Units

Ball & roller bearings

Upgraded Explorer series

bearings

High precision bearings

Sleeves

Bearing Housings

Lock nut & lock washers

Linear motion bearings

Guiding system, ball & roller

screw

Ball bearing units –

UC range

Optimise harvest in lowest budget and worry-free maintenance with Sortex rice sorting machine

Harvesting season brings hope and smiles on the face of farmers but sub-standard harvesting and sorting machines can ruin the hopes if productivity and quality is compromised resulting from such unfit machines. To tackle these issues and give the best reward for farmer’s on-field efforts Atlas Copco launches its revolutionary state-of-the-art and mechanically advanced rice sorting machine – the Sortex Rice Sorting machine G15L-22.

The machine uses an oil-injected rotary screw compressor to optimise harvesting and sorting. To overcome the current challenges of operating cost and low quality rice output, this machine is tuned to operate at the lowest operating expenses with guaranteed uptime and assured best quality rice output time and again.

Designed to ensure low installation and maintenance cost this advanced machine is operator friendly and uses new-age controllers which are simple, powerful and reliable. Manufactured with high-grade metals this machine is rugged, strong and uses a flexible drive suitable for 100% duty cycle. While most of the machine face right quality air issues with Sortex rice our G15L-22 machine integrates compressor, Dryer, Filter and receiver into one machine for enhanced purity and inbuilt refrigeration air dryer and low pressure drop 2-in-1 filtration specifically for Sortex rice.

G15L-22’s space-saving design occupies a limited area on your factory floor eliminating any space issues and is highly reliable which is designed for 46C’s and dust prevention as it operates on a time-tested, proven rotary screw compressor technology and comes with HD filter, pre-filter, and bigger coolers. With a vast network of dealerships across India, the availability of spares or factory trained technicians is never a problem for its timely and proper maintenance.

With more than 140 years of innovation and experience, Atlas Copco delivers products and services to help maximize your company’s efficiency and productivity. We are dedicated to offering high air quality at the lowest possible cost of ownership. Call or mail us to know how your rice sorters can perform better.

Essential Tips to maintain air compressor during summers

Summer has arrived and that too in full intensity. As peak summer heat is considerable dangerous for human body, same goes with the air compressors. The high ambient heat, if not managed properly can cause severe repercussion to the air compressor and may lead to high production loss and downtime. It also makes your air compressor less efficient and results in high power cost.

Here are the few essential tips from the Atlas Copco service experts to maintain compressed air system in the summer season and to safegaurd from the losses.

The first and foremost activity which is recommended at all seasons is daily inspection of compressors which mainly includes checking of oil level, air filter, leakages, noise, etc followed by close monitoring of the compressor parameters from controller/Elektronikon. These parameters can be recorded by remote monitoring tools like SMARTLinkas this will help you to understand the performance of the machine and accordingly necessary preventive action can be taken.

- Clean Cooler – Blocked or clogged coolers can cause an air compressor to overheat on hot summer days. Hence, ensure coolers are properly cleaned before the peak heat hits the compressors.

- Check Drains – Higher humidity in the summer causes more condensate to come out of drains. Be sure drains are in perfect working order so they can handle the extra flows.

- Clean Air and Oil Filters – Dirty filters lead to pressure drops, but clean filters will reduce energy consumption. So, ensure to clean or replace compressor air and oil filters.

- Check Compressor Oil – High ambient heat can decrease oil life expectancy. Using the genuine oil & oil filter and following the recommended oil change intervals will ensure that your compressors runs cool and consume less energy.

- Check Ventilation – Proper ventilation of air compressor room is important to route hot air out of the compressor room using ducts and vents.

- Adjust Water Cooling Systems – With water-cooled compressors, adjust the temperature & flow of water entering the compressor to ensure that it is cool enough for summer conditions.

As always, consult a compressed air specialist for recommendations specific to your facility’s processes.

Rotary Screw compressor

Rotary (or twin) screw compressor is widely preferred for large industrial applications in the food industry, automated manufacturing systems and to operate large high power air tools such as jackhammers, pneumatic pumps, riveting tools, sand blasting operation, industrial paint systems and impact wrenches. This compressor uses a rotary type positive displacement mechanism to provide large amounts of continuous and uniform supply of high-pressure air.

Advantage of such compressors over other air and piston compressors are numerous like they are convenient when continuous supply of high pressure air is needed, safe to operate, can operate continuously under extreme load and weather conditions without damaging other crucial components of the machine, energy saving and easy to maintain, runs quietly despite massive air flow, requires much lesser amounts of oil and are built to last for ages.

Basically there are two types of rotary screw compressor i.e the oil-free and secondly the oil-injected rotary screw compressor and another relatively new entrant is the conical screw compressor. Selection of the right type of compressor is important depending upon which type of application it is going to be used in. If there is no immediate need for oil-free compressed air, the more economic way is to go with an oil lubricated unit like an oil-injected screw compressor. Oil-free compressors carry a much greater cost. Although, there are traces of oil in compressed air, those can be cleaned up further by utilizing proper quality air product.

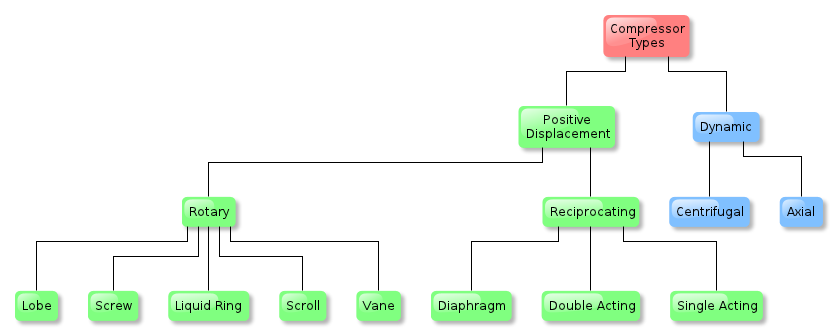

What are Compressors and What are Their Types?

A compressor is a machine that increases the pressure of a gas by bringing down its volume. An air compressor is a type of gas compressor that converts power into some possible energy stored in compressed air. There are many types of compressors, which are as follows:

Positive Displacement, Dynamic and hermetically sealed, open or semi-hermetic. Again the Positive Displacement and Dynamic compressors are subdivided into the following heads:

Positive displacement:

a. Reciprocating compressors

b. Ionic liquid piston compressor

c. Rotary screw compressors

d. Rotary vane compressors

e. Rolling piston

f. Scroll compressors

g. Diaphragm compressors

Dynamic compressor

a. Air bubble compressor

b. Centrifugal compressors

c. Diagonal or mixed-flow compressors

d. Axial-flow compressors

Applications of compressors:

Applications of gas compressors are manifold.

a. Compressors are used to transfer purified natural gas from the production site to the consumer point.

b. Compressors are used in many plants like Petroleum refineries, natural gas processing plants, petrochemical and chemical plants and similar other plants.

c. Compressors are used in refrigerators and air conditioners to move heat.

d. In order to fill high pressure cylinders required for medical, welding and other uses, compressors are needed.

e. Compressors are required in the manufacturing and blow moulding of PET plastic bottles and containers.

Drypit Nonclog Sewage Wastewater Pump

Optional Features

Mounting: Vertical Delivery flange orientation change possible Bush Bearing

Material of Construction

Cast Iron, Bronze, Ductile Iron, Cast Steel, Ni Resist, Stainless Steel Duplex Stainless Steel & special alloys

Applications

Municipal Raw Sewage Transfer Sewage treatment plants Effluent treatment plants Dirty Water in Industry Sugar Mills

Prime Movers

Electric motors

Design Features

End Suction Top Discharge Mounting: Horizontal Stage: Single Casing with hand hole inspection cover Mechanical Seal/ Gland Packing Large Free Passage up to 200 mm Grease lubricated antifriction bearing

Flow Upto Head up to Temperature up to DN

8000 m3/hr* 70 m* 90oc* 50 – 800*

Multi-Pump Booster

Optional Features

Horizontal/ Vertical pumps Variety of panels with floating VFD/ with dedicated VFD/ Without VFD, with PLC/without PLC panels with customized requirements

Material of Construction

Casing – SS(304/316L) /Cast Iron Impeller – SS(304/316L)

Applications

Pressure Boosting for Commercial complexes, Hotels, Industries, etc.

Prime Movers

Electric motors

Design Features

Multi-pump Pressure Boosting system from two up to eight pumps in Stainless Steel construction Fitted on a common baseplate with vibration dampers

Flow Upto Head up to Temperature up to DN

900 m3/hr* 235 m* 120oc 32 – 100