Oil-free centrifugal compressors

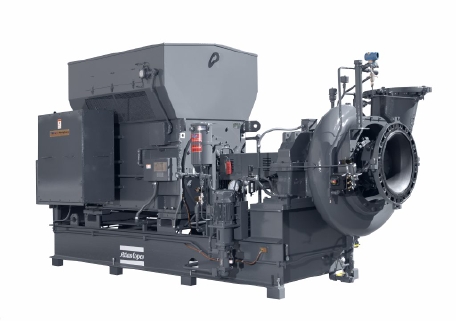

ZH+: Oil-free centrifugal compressors, 400-2750 kW, 500-3500 hp.

Delivered as a plug-and-run package, Atlas Copco’s ZH+ oil-free centrifugal compressors are designed to save

Read More

ZH 350+: Oil-free high-speed drive centrifugal compressors, 350 kW, 470 hp.

Atlas Copco’s ZH 350+ oil-free centrifugal compressors are designed to save you energy. Operating at

Read More

ZH: Oil-free centrifugal compressors, 500-2750kW/ 600-3500HP

Proven turbo technology Equipped to save energy and guarantee reliability, Atlas Copco’s ZH are ideal

Read More

ZB 300-900: Oil-free integrally geared centrifugal blowers, 300-900 kW, 415-1250 hp.

In a highly competitive marketplace, Atlas Copco’s ZB 300-900 single-stage, integrally geared centrifugal blowers stand

Read More

ZB 100-160 VSD: Oil-free Variable Speed Drive centrifugal air compressors, 100-160 kW, 135-215 hp.

Atlas Copco’s low pressure ZB 100-160 VSD blowers guarantee a continuous, highly reliable, energy-efficient and

Read More