Customer benefits

Exceptional reliability – The advanced design of ZB 300-900 blowers incorporates tilting pad and low vibration turbo technology which contribute to exceptional reliability and production continuity. The use of top-quality AGMA A4/DIN 5 gears ensures the highest levels of production uptime.

Maximum energy savings – The ZB 300-900 range cuts your costs: the unique bearing design coupled with the turbo compression system provides the highest air volume at the lowest energy consumption.

Easy maintenance – ZB 300-900 blowers will save you time and costs due to easy serviceability.

Certified 100% oil-free – All ZB blowers provide you with 100% pure, clean air that complies with ISO 8573-1 CLASS 0 (2010) certification. CLASS 0 means zero risk of contamination; zero risk of damaged or unsafe products; zero risk of losses from operational downtime; and zero risk of damaging your company’s hard-won professional reputation. In 2006 Atlas Copco was the first manufacturer in the world to receive such certification on an oil-free compressor.

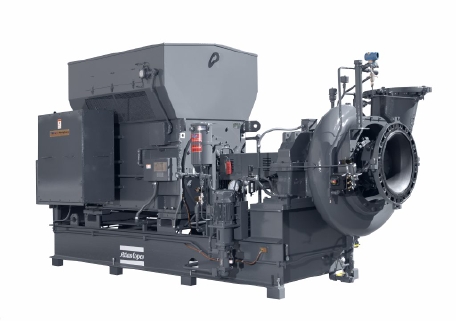

In a highly competitive marketplace, Atlas Copco’s ZB 300-900 single-stage, integrally geared centrifugal blowers stand out from the crowd. One reason is an innovative energy-saving design for increased efficiency at maximum flow. The result is a continuous, reliable, energy-efficient supply of air – certified 100% oil-free according to ISO 8573-1 CLASS 0 (2010). In short, the ZB 300-900 stands for reliable, cost-effective performance in a variety of demanding applications.

| Technical Specifications | |

|---|---|

| Capacity FAD (l/s) | 972 – 11667 l/s |

| Capacity FAD (m³/h, cfm) | 3500 – 42000 m³/h |

| Working pressure | 0.2 – 0.95 bar(e) |

| Installed motor power | 300 – 1120 kW |